- Call Us

1300 29 35 32 - Email Us

sales@cwelecautomation.com.au

Introduction:

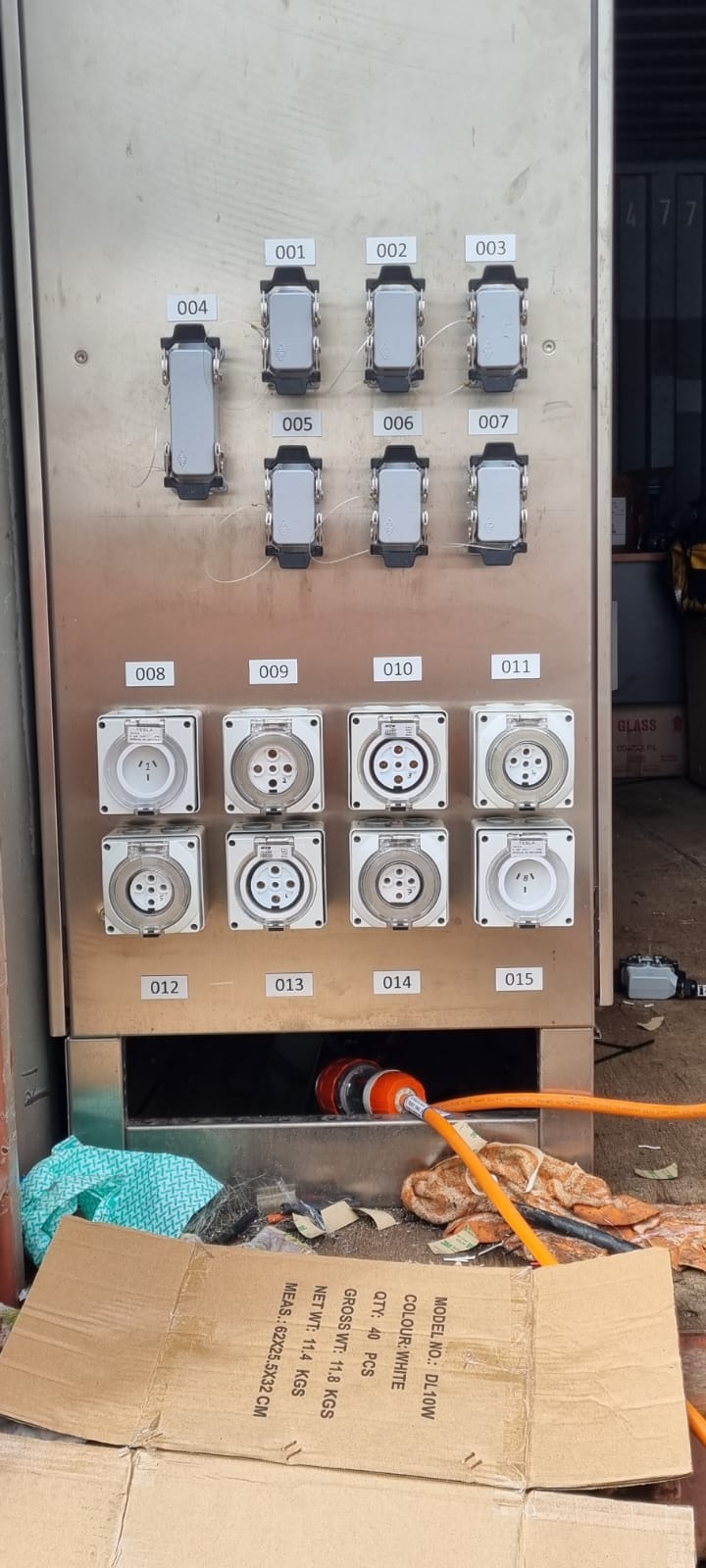

In today’s fast-paced business environment, adaptability and efficiency are paramount. When it comes to electrical systems, the need for flexibility and ease of use becomes even more critical, especially for companies operating in multiple locations. This blog post highlights a solution provided by our team to Cleanaway, a valued customer, in the form of a “plug and play” electrical cabinet. With the goal of simplifying system relocation without the hassle of rewiring, we devised a versatile solution that empowers Cleanaway to seamlessly connect their control board, three-phase motors, and control gear at various sites. Let’s delve into the details of this innovative project.

The Challenge:

Cleanaway, a dynamic company specializing in waste management services, faced a significant hurdle in relocating their control board and associated equipment to different sites. Rewiring the entire system at each new location was a time-consuming and cost-intensive process. Moreover, the risk of errors and damage associated with rewiring posed a significant operational concern. To overcome these challenges, Cleanaway sought an effective solution that would enable them to quickly and effortlessly connect their control board and equipment at various sites.

The Solution:

Understanding Cleanaway’s requirements and the need for a flexible, user-friendly approach, our team devised a “plug and play” electrical cabinet. The cabinet served as a centralized hub that allowed for easy relocation of the control board, three-phase motors, and control gear without the need for rewiring. We labeled each component for effortless operator use, ensuring a seamless and efficient setup process.

Benefits:

- Time and Cost Savings: By eliminating the need for rewiring at every new location, Cleanaway can significantly reduce downtime and associated costs. The “plug and play” feature enables them to swiftly set up their control board and equipment, streamlining their operations.

- Enhanced Flexibility: The modular nature of the electrical cabinet empowers Cleanaway to adapt to evolving requirements and changing site configurations effortlessly. They can efficiently reposition their control board and equipment, catering to specific operational needs.

- User-Friendly Operation: With clearly labeled components, operators can easily identify and connect the necessary equipment without the need for specialized technical knowledge. This reduces the potential for errors and simplifies training requirements for new staff members.

- Minimized Risk of Damage: The risk of wiring errors or damage during the relocation process is significantly reduced, ensuring the longevity and reliability of the electrical system. Cleanaway can maintain uninterrupted operations and focus on their core business objectives.

Conclusion:

Innovation and practicality go hand in hand when addressing complex challenges. By designing a “plug and play” electrical cabinet for Cleanaway, our team has successfully provided a solution that simplifies the relocation of their control board and associated equipment. This modular and adaptable system offers immense benefits, including time and cost savings, enhanced flexibility, user-friendly operation, and minimized risk of damage. As businesses strive for operational efficiency and agility, such solutions pave the way for streamlined operations and future growth.

At our company, we are committed to delivering tailored and ingenious electrical solutions to meet the unique needs of our clients. If you require innovative electrical system designs or expertise, contact us today to explore how we can assist you in achieving your goals.